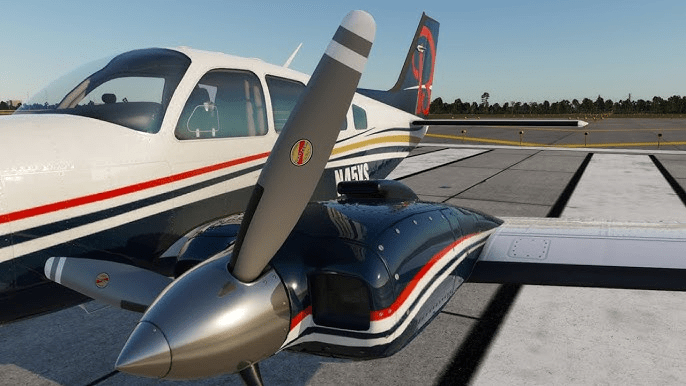

Mastering Complex Aircraft Emergencies in X-Plane 12 Baron 58.

Pilot’s Emergency Guide for X-Plane 12 included will assist you when flying complex aircraft like the Beechcraft Baron 58 which is an incredible experience in X-Plane 12 and other flight simulators.

With features like multi engine operation, controllable propellers, mixture settings, retractable landing gear, and intricate electrical and fuel systems, these aircraft offer rich, realistic training environments. However, they also demand more from the pilot especially when things go wrong.

In this pilot’s emergency guide for X-Plane 12 blog, we’ll explore the most common system failures in complex aircraft and how to manage them effectively. Whether you’re flying the Baron 58, a Piper Seneca, or a Cessna 310, this guide will help you understand the systems, identify failures, and respond appropriately using both real-world and simulator-proven techniques.

Understanding Complex Aircraft Systems

Before diving into emergencies, it’s essential to understand what makes these aircraft ‘complex’:

- Multi-Engine Operation: Two or more engines provide redundancy but increase workload, especially during engine-out scenarios.

- Controllable-Pitch Propellers: Adjustable propellers improve efficiency but introduce potential failures like overspeed or feathering problems.

- Mixture Controls: Required for optimal engine performance at altitude, improper use can lead to engine roughness or failure.

- Retractable Landing Gear: Reduces drag but introduces potential mechanical or hydraulic failure.

- Electrical Systems: Often dual-alternator and battery setups, which power avionics and instruments.

- Vacuum Systems: Used to power gyroscopic flight instruments in some aircraft, though increasingly replaced by electronic backups.

These systems enhance performance and realism but also increase the number of potential failure points.

Common Multi-Engine System Failures and Emergency Procedures

1. Engine Failure (Complete or Partial)

Symptoms: Loss of thrust, yaw to one side, drop in RPM, rough running.

Response:

- Maintain control and pitch for Vyse (best single-engine rate of climb).

- Identify the failed engine (“dead foot = dead engine”).

- Verify by retarding throttle on suspected engine.

- Feather the propeller to reduce drag.

- Cut off fuel, mixture, and ignition on the dead engine.

- Secure the engine and consider diverting.

In multi engine aircraft the loss of one engine can still mean quite a lot of difficulty if your heavy weight wise, and the aircraft can struggle to keep good performance. Losing a single engine requires a lot of rudder input either manually or with rudder trim.

Ensuring you don’t get to slow is important when landing because the power available may not be enough to keep you flying if you are descending quickly. Its dangerous.

2. Propeller Overspeed (Runaway Prop)

Symptoms: Loud noise, high RPM, strong vibration.

Response:

- Throttle back on affected engine.

- Prop lever to full decrease RPM.

- If RPM doesn’t respond, shut down and feather the engine.

In all emergency situations ensure you:

- Identify – The Problem Engine

- Verify – Your about to Turn off the correct engine!

- Feather – The Propeller on the Bad engine – Reduce Induced drag.)

3. Alternator Failure (Single or Dual)

Symptoms: Voltage drop, warning lights, loss of electrical systems.

Response:

- Identify failed alternator.

- Attempt reset via circuit breakers or switches.

- Load shed unnecessary electrical equipment.

- Land as soon as practical.

This issue is unlikely to be a major concern, as your setup should include two alternators and batteries to maintain operations based on power distribution. Critical systems like avionics are typically designed with multiple independent power sources or buses, ensuring redundancy.

This safeguards electrical distribution so that if one generator fails, the other can still provide sufficient avionics support for a safe flight.

4. Fuel Imbalance

Symptoms: Aircraft rolls or yaws unexpectedly, visible fuel tank discrepancy.

Response:

- Check fuel gauges.

- Use crossfeed or alternate tanks to balance.

- Monitor fuel use more frequently.

Fuel balancing in modern aircraft is often automated, but in older models, pilots may need to manually switch tanks to maintain balance and stay within center of gravity (C of G) limits. In flight, an imbalance might not be immediately noticeable unless a tank runs dry, which would certainly be a serious issue.

However, the greater concern typically arises on the ground, where having one wing tank full and the other empty could create stability challenges.

5. Fuel Pump Failure (Engine or Auxiliary)

Symptoms: Engine roughness, pressure fluctuations.

Response:

- Activate backup pump.

- Monitor engine performance.

- Consider diverting if pressure remains unstable.

Fuel pump failure—whether engine-driven or auxiliary—can pose a serious risk to aircraft operation. In low-wing aircraft, where fuel must be pumped rather than gravity-fed, the engine-driven pump is the primary source of fuel delivery.

If it fails, the auxiliary (boost) pump can be activated to maintain fuel flow and prevent engine power loss. Pilots are trained to recognize signs of fuel starvation and follow emergency procedures, which may include switching tanks, adjusting fuel mixture, or descending to lower altitudes to mitigate vapor lock.

Regular maintenance and system checks help reduce the likelihood of pump failure, ensuring safe and reliable flight operations.

Boost Pumps or regularly used during takeoff and landing as a backup should a main pump fail during a CRITICAL PHASE OF FLIGHT.

6. Gear Extension/Retraction Failure

Symptoms: Gear does not fully extend or retract; unsafe gear light.

Response:

- Use emergency gear extension handle.

- Ensure 3 green lights or visually verify gear position.

- Prepare for a possible gear-up landing.

Landing gear is out of the list of mechanical failures one that come up somewhat often. We have all seen videos of aircraft landing without one or all of its landing gear deployed. Its a dangerous time but can be managed with good piloting skills.

Being that engines are around $60,000 dollars each on a twin engine aircraft plus the adjustable propellers many try to fly in and turn off engines when landing is assured. This means the engines may not be damaged when the aircraft and propellers contact the ground. It’s a pilot’s choice.

Got Insurance, then do what is the best and safest for you as PIC (Pilot In Command). It’s always your choice and saving life is more important than banging up the aircraft.

7. Flap System Malfunction

Symptoms: Roll or yaw instability during flap deployment.

Response:

- Stop flap extension.

- Retract flaps slowly and symmetrically if possible.

- Increase airspeed for better control.

Flap system failures are uncommon but can occur, with one of the most critical risks being asymmetric deployment—where one flap extends while the other remains stuck. This creates a significant difference in lift between the wings, potentially leading to dangerous control issues.

Many aircraft incorporate safety mechanisms to detect and mitigate such imbalances, preventing further deployment if asymmetry is detected. Pilots train extensively for flapless landings, which require maintaining a higher approach speed and ensuring enough runway length for a safe touchdown.

Swing-wing aircraft like the F-111 have successfully landed with their wings swept back, demonstrating that proper speed management and planning are key. While a longer runway is preferable, a skilled pilot can safely execute such landings under various conditions.

THere are many instances where this pilot’s emergency guide for X-Plane 12 can get you home safely!

8. Vacuum System Failure

Symptoms: Loss of attitude indicator and heading indicator.

Response:

- Use backup electric attitude indicators.

- Avoid IMC.

- Divert if flying in instrument conditions.

Vacuum pumps in aircraft primarily power gyroscopic flight instruments, including the attitude indicator, heading indicator, and turn coordinator. These instruments are crucial for maintaining situational awareness, especially in instrument flight conditions where external visual references are limited.

When a vacuum pump fails, the affected instruments gradually lose accuracy, potentially leading to disorientation and loss of control, particularly in poor visibility.

Electrically powered gyroscopic instruments (e.g., an electric attitude indicator).

- Dual vacuum pumps in some twin-engine aircraft.

- Standby vacuum systems that can temporarily restore functionality.

Common Causes of Failure

Vacuum pumps typically fail due to:

- Wear and tear—dry pumps degrade over time, with failure often occurring around 500 flight hours.

- Oil or solvent contamination, leading to internal damage.

- Foreign object ingestion, causing rotor or vane fragmentation.

- Overheating, which can lead to seizure.

- Incorrect installation or rotation direction, reducing efficiency.

Regular maintenance and system checks are essential to prevent unexpected failures and ensure safe flight operations. If a vacuum pump fails, pilots must rely on backup instruments and partial panel techniques to maintain control until landing.

9. Fire (Engine or Electrical)

Symptoms: Smoke, fire warning light, burning smell.

Response:

- Engine Fire:

- Mixture cut-off

- Fuel selector off

- Ignition off

- Feather prop

- Execute emergency descent if required

- Electrical Fire:

- Master off

- All switches off

- Ventilate cabin

- Extinguish if possible

Aircraft fires can originate from engine or electrical systems, each with distinct causes. Engine fires often result from fuel leaks, overheating, or oil contamination, leading to ignition within the engine compartment.

Electrical fires, on the other hand, typically stem from short circuits, worn insulation, or overheating components, which can cause sparks or arcing. In both cases, proper maintenance, system monitoring, and emergency procedures—such as shutting down affected systems or using onboard fire suppression—are critical to preventing escalation and ensuring flight safety.

10. Pitot-Static System Blockage

Symptoms: Inaccurate airspeed, altitude, or VSI readings.

Response:

- Turn on pitot heat.

- Use alternate static source if equipped.

- Cross-check GPS or backup instruments.

A Pitot-Static System blockage is dangerous because it disrupts critical flight instruments, including the airspeed indicator, altimeter, and vertical speed indicator, leading to inaccurate readings and potential loss of situational awareness.

Blockages can occur due to ice formation, insect nests, debris, or failure of heating elements in the pitot tube. Pilots can identify a blockage by noticing erratic or frozen instrument readings, such as an airspeed indicator stuck at a constant value or an altimeter failing to respond to altitude changes.

Proper pre-flight inspections, pitot heat activation, and awareness of abnormal instrument behavior help mitigate risks and ensure safe flight operations.

11. Brake or Nosewheel Steering Failure

Symptoms: Loss of control during taxi, takeoff, or landing rollout.

Response:

- Plan for a longer landing.

- Use rudder and differential thrust.

- Prepare for runway excursion.

This failure can be delt with by landing on the mains and holding the nose off as long as possible. Landing with no gear extended is the second option. As PIC its your decision and when the main gear is down turning off the engines can save valuable engine damage but props are going to get redesigned! As PIC its your choice!

Pilot’s Emergency Guide for X-Plane 12 – Download.

Practicing Failures in X-Plane 12

One of the best features of X-Plane 12 is its ability to simulate these failures realistically. You can trigger failures manually or randomly in the Failures menu. Practicing with a checklist and realistic weather settings builds the muscle memory and confidence required in emergencies.

Use the downloaded Complex Aircraft Emergency Quick Guide PDF (available at the end of this post) as a printable kneeboard or onscreen reference.

Conclusion

Mastering system failures in complex aircraft like the Baron 58 is a rite of passage for any serious simulator pilot. While emergencies can seem intimidating, a calm, practiced approach will keep your virtual passengers safe and your airmanship sharp. Remember to:

- Know your aircraft systems.

- Practice regularly.

- Use checklists and memory items.

- Fly the airplane first—aviate, navigate, communicate.

With time and practice, you’ll gain the confidence to handle any emergency X-Plane 12 throws your way.

Download: Complex Aircraft Emergency Quick Guide PDF

Fly safe, and keep your skills sharp!

Author

Brendon McAliece (Aka Gunnie) is a military veteran with 23 years working on Jet Fighters, their weapons systems and ejection seat/module systems as well as munitions and R&D. Involved with flight simulation since the 1980s, he has flown all the major flight simulators over the years.

He is an Australian expat who has lived in Malaysia, UK, Saudi Arabia and more recently Thailand. He is a multi-lingual blogger who loves to share his life experiences here on LetsFlyVFR.com and DreamingGuitar.com, with his lifestyle and Travel experiences Blog plus his Dreaming Coffee website.

Learn More @

DreamingGuitar.com – DreamingCoffee.com – LetsFlyVFR.com

( HOME – BLOG – SHOP – ABOUT )

This page has been viewed 0 times.

As an Amazon affiliate I may benefit from qualifying sales.

One response to “Mastering Complex Aircraft Emergencies in X-Plane 12 Baron 58.”